Walbro FR Series Reciprocating Fuel Pumps - Marine and Industrial

**Notice: Special Order Items - Walbro Marine & Industrial Fuel Pumps Reciprocating Mechanical Fuel Pumps**

All Walbro Marine & Industrial Fuel Pumps Reciprocating Mechanical Fuel Pumps are subject to special order. Due to their unique nature and low demand, these mechanical fuel pumps may require additional processing and delivery time.

**What to Expect:**

- Manufacturer Delays: Due to the limited demand and specialized nature of the product, delays from Walbro, our esteemed manufacturer, are possible.

- Extended Processing Time: Please anticipate a longer processing time before your order ships.

Walbro Reciprocating Fuel Pumps

Walbro's FR fuel pump series are designed to be more efficient by requiring less current while providing a better flow, and with higher quality bellows that are built to last longer. The Reciprocating FR Fuel Pump series replaces the 2000 series and 6000 series fuel pumps which were installed in many boats, vehicles, other marine and industrial machines and even stoves.

Formerly branded as AutoPulse, Stewart Warner, Dupree and AC. The 2000 and 6000 fuel pumps use outdated technology and upgrading to the higher quality and more efficient fuel pump is recommended.

Walbro’s FR series reciprocating fuel pumps are durable units suitable for commercial and industrial use. Designed for gasoline or diesel fuels 12 or 24 volt Wide variety of design configurations

STANDARD FEATURES- ALL MODELS

- Current requirement: < 2 amps average

- Reverse polarity protected up to 60 minutes

- Self priming (dry lift) of more than 120cm (48”)

- Dry run to four (4) hours

- Compatible with all commercially available pump grade gasoline, gasohol. diesel or bio-diesel

- Operating temperature: -40 ~ +70C (-40 ~ +155F)

- Transient voltage protected to 100 volts

- Tested per CFR Title 33: 183.590 Fire Test and 183.410 Ignition Protection (USCG)

FRA, FRD

FRA MODEL UNIQUE FEATURES

For applications where low cost and good durability are required

- Flow: to 190 lph (52 gph)

- Continuous duty life (diesel fuel): >5000 hrs

- Weight: 0.74 kg (1.63 lbs)

- Pump cycles continuously when power is on

FRD MODEL UNIQUE FEATURES

For applications where battery life, low noise and better durability are important

- Flow: to 210 lph (55 gph)

- Ampere hours: up to 70% less than FRA & FRC

- Continuous duty life (diesel fuel): >10000 hrs

- Weight: 0.75 kg (1.65 lbs)

- Pump cycles only when fuel is demanded

FRB, FRC

FRB MODEL UNIQUE FEATURES

For applications where battery life, low noise and best durability are important and fuel quality is questionable

- Flow: to 225 lph (60 gph)

- Ampere hours: up to 70% less than FRA & FRC

- Continuous duty life (diesel fuel): >18000 hrs

- Weight: 0.83 kg (1.83 lbs)

- Pump cycles only when fuel is demanded

- Replaceable filter

FRC MODEL UNIQUE FEATURES

For applications where low cost and better durability are important and fuel quality is questionable

- Flow: to 210 lph (55 gph)

- Continuous duty life (diesel fuel): >10000 hrs

- Weight: 0.83 kg (1.83 lbs)

- Pump cycles continuously when power is on

- Replaceable filter

CONFIGURATION OPTIONS AVAILABLE

Notes:

1. Lead wire and electrical ground options

- A. Two wire: Must be battery or vehicle grounded by customer, does not have internal ground (Body must be externally grounded for gasoline applications)

- B. Two wire: Must be battery or vehicle grounded by customer and includes internal ground (Suitable for gasoline)

- C. One wire: Pump must be battery or vehicle grounded by customer and includes internal ground (Suitable for gasoline)

2. Lead wire lengths and electrical connectors per customer requirement

3. Requires standard inlet and outlet valves and an optional outlet check valve

|

OPTION |

FRA |

FRB |

FRC |

FRD |

|

12 volt |

X |

X |

X |

X |

|

24 volt |

X |

X |

X |

X |

|

Lead wires, connectors and electrical ground (see notes 1 & 2) |

A, B, C |

A |

A, B, C |

A |

|

Output pressure: 20 kpa (3 psi) |

X |

X |

X |

X |

|

Output pressure: 35 kpa (5 psi) |

X |

X |

X |

X |

|

Output pressure: 50 kpa (7 psi) |

X |

X |

X |

X |

|

Output pressure: 70 kpa (10 psi) |

X |

X |

X |

X |

|

Output pressure: 90 kpa (13 psi) |

X |

X |

X |

X |

|

Self priming (dry lift) of more than 305cm (120”) (see note 3) |

X |

X |

X |

X |

|

Standard external finish (meets ASTM B-117 (96) hr salt spray) |

X |

X |

X |

X |

|

Marine external finish (meets ASTM B-117 (1000) hr salt spray) |

X |

X |

X |

X |

|

Bowl drain (see Figures 1 and 3) |

X |

X |

||

|

Transparent fuel bowl- not USCG approved (see Figure 2) |

X |

X |

||

|

Inlet filter: 70 micron |

X |

X |

||

|

Inlet filter: 420 micron |

X |

X |

||

|

Magnetic trap |

X |

X |

||

|

Inlet fuel fitting thread- 1/8-27 NPSF |

X |

X |

X |

X |

|

Inlet fuel fitting thread- 1/4-18 NPSF |

X |

X |

||

|

Outlet fuel fitting thread- 1/8-27 NPSF |

X |

X |

X |

X |

|

Outlet fuel fitting thread- 1/4-18 NPSF |

X |

X |

X |

X |

|

Internal outlet check valve (available with 1/8-27 NPSF only) |

X |

X |

X |

X |

|

External outlet check valve - 1/8-27 NPSF (see Figure 4) |

X |

X |

X |

X |

|

External outlet check valve - 1/4-18 NPSF (see Figure 4) |

X |

X |

X |

X |

|

Straight fuel fitting: 1/8-27 NPSF to 5/16 hose barb (see Figure 5) |

X |

X |

X |

X |

|

Straight fuel fitting: 1/4-18 NPSF to 5/16 hose barb (see Figure 5) |

X |

X |

X |

X |

|

45° fuel fitting: 1/8-27 NPSF to 5/16 hose barb (see Figure 6) |

X |

X |

X |

X |

|

45° fuel fitting: 1/4-18 NPSF to 5/16 hose barb (see Figure 6) |

X |

X |

X |

X |

|

90° fuel fitting: 1/8-27 NPSF to 5/16 hose barb (see Figure 7) |

X |

X |

X |

X |

|

90° fuel fitting: 1/4-18 NPSF to 5/16 hose barb (see Figure 7) |

X |

X |

X |

X |

|

Mounting (see “MOUNTING AND FITTING LOCATIONS AND DETAILS”) |

F or G |

F or G |

F or G |

F or G |

|

Fitting location (see “MOUNTING AND FITTING LOCATIONS AND DETAILS”) |

H, J |

H, K |

H, K |

H, J |

FUEL PUMP SIZING GUIDELINES

To calculate pump size requirements:

1) Engine fuel requirements (in lph) shown in the above charts is an approximation based on the following calculation:

a. Two Stroke engines = (HP)(.40) (based on BSFC of .67# /HP/HR)

b. Four stroke or direct injected two stroke engines = (HP)(.30) (based on BSFC of .50# /HP/HR)

c. Diesel engines = (HP)(.25) (based on BSFC of .42# /HP/HR)

2) Consider an additional hot fuel (for gasoline applications) allowance of up to 30% (application specific)

3) Consider an additional fuel allowance for injector pump cooling (diesel applications only)

4) Consider an additional safety allowance for certain applications where fuel lines, filters, etc. create abnormal pressure losses (confirmation by testing recommended)

5) For additional application assistance, contact Walbro Engine Management

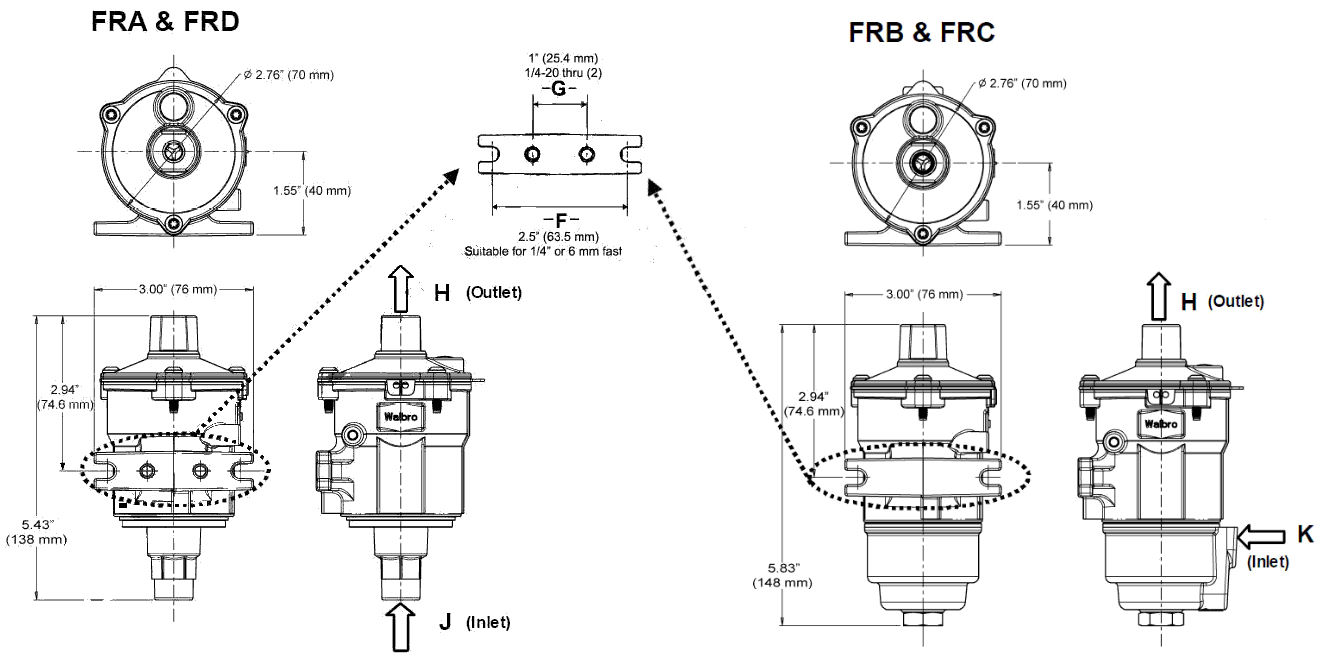

OVERALL DIMENSIONS, MOUNTING DETAILS AND FITTING LOCATIONS

Cross Reference

| Brand | Part Number | Continuous Duty | Operates on Fuel Demand |

| AC | EP12 | FRA-1 | FRD-1 |

| AC | EP12S | FRA-1 | FRD-1 |

| AC | EP42 | FRA-2 | FRD-2 |

| AC | EP42S | FRA-2 | FRD-2 |

| AC | EP43 | FRA-1 | FRD-1 |

| Airtex | E12 | FRA-1 | FRD-1 |

| Airtex | E12S | FRA-1 | FRD-1 |

| Airtex | E14 | FRA-2 | FRD-2 |

| Airtex | E16S | FRA-2 | FRD-2 |

| Airtex | E19 | FRA-2 | FRD-2 |

| Airtex | ES012AX | FRA-1 | FRD-1 |

| Autopulse | 2101 | FRA-1 | FRD-1 |

| AutoPulse | 2120 | FRA-2 | FRD-2 |

| Autopulse | 2240 | FRA-2 | FRD-2 |

| Big A | BAE8012 | FRA-1 | FRD-1 |

| Blackstone | EP12B | FRA-1 | FRD-1 |

| Blackstone | EP42 | FRA-2 | FRD-2 |

| Borg Warner | EP12B | FRA-1 | FRD-1 |

| Borg Warner | EP42B | FRA-2 | FRD-2 |

| Borg Warner | EP42E | FRA-2 | FRD-2 |

| Borg Warner | EP42E | FRA-1 | FRD-1 |

| Canadian Tire | 23-6561-4 | FRA-2 | FRD-2 |

| Canadian Tire | 23-6576-0 | FRA-1 | FRD-1 |

| Carter | P60378 | FRA-1 | FRD-1 |

| Dupree | 801 | FRA-1 | FRD-1 |

| Dupree | 840 | FRA-2 | FRD-2 |

| Mr Fuel | Std Pressure | FRA-1 | FRD-1 |

| Mr Fuel | Low Pressure | FRA-2 | FRD-2 |

| EZON | AG801 | FRA-1 | FRD-1 |

| Federal Mogul | P60378 | FRA-1 | FRD-1 |

| IPS | 12-3614 | FRA-2 | FRD-2 |

| IPS | 12-3615 | FRA-2 | FRD-2 |

| IPS | 12-3616 | FRA-1 | FRD-1 |

| Master | ES012M | FRA-1 | FRD-1 |

| NSN (Military) | 2910-00-453-6105 | FRA-1 | FRD-1 |

| Repco | 151-2000 | FRA-1 | FRD-1 |

| Repco | 151-2001 | FRA-2 | FRD-2 |

| Repco | 151-2080 | FRA-1 | FRD-1 |

| Repco | 151-2092 | FRA-2 | FRD-2 |

| Repco | 151-2101 | FRA-2 | FRD-2 |

| Repco | 151-2102 | FRA-2 | FRD-2 |

| Repco | 151-2168 | FRA-1 | FRD-1 |

| Sorenson | PE12 | FRA-1 | FRD-1 |

| Sorenson | PE13 | FRA-2 | FRD-2 |

| Sorenson | PE14 | FRA-2 | FRD-2 |

| Sorenson | PE15 | FRA-1 | FRD-1 |

| Standard Motor Products | EFP1S | FRA-1 | FRD-1 |

| Stewart Warner | D235A | FRA-1 | FRD-1 |

| Walbro | 2101H | FRA-1 | FRD-1 |

| Walbro | 2108 | FRA-1 | FRD-1 |

| Walbro | 2113 | FRA-2 | FRD-2 |

| Walbro | 2161 | FRA-1 | FRD-1 |

| Walbro | 2192 | FRA-1 | FRD-1 |

| Walbro | 2212 | FRA-1 | FRD-1 |

| Walbro | 2212AP | FRA-2 | FRD-2 |

| Walbro | 2214 | FRA-1 | FRD-1 |

| Walbro | 2214AP | FRA-1 | FRD-1 |

| Walbro | 2304 | FRA-1 | FRD-1 |

| Walbro | 2305 | FRA-2 | FRD-2 |

| Walbro | 2310 | FRA-1 | FRD-1 |

| Walbro | 2310-29 | FRA-1 | FRD-1 |

| Walbro | 2310AP | FRA-1 | FRD-1 |

| Walbro | 2310HL | FRA-1 | FRD-1 |

| Walbro | 2312 | FRA-2 | FRD-2 |

| Walbro | 2312-29 | FRA-2 | FRD-2 |

| Walbro | 2312HL | FRA-2 | FRD-2 |

| Walbro | 2312P | FRA-2 | FRD-2 |

| Walbro | 2318 | FRA-2 | FRD-2 |

| Walbro | 2401 | FRA-1 | FRD-1 |

| Walbro | 2402 | FRA-2 | FRD-2 |

FAQ

- What material is the pump made of?

- The FR pumps have an aluminum die cast body. Most models have a protective dichromate finish (96 hours) and the marine models have additional corrosion protection (1,000 hours), meeting the ASTM B-117 spec. for salt spray.

- Can the pump be used for both negative and positive ground systems?

- Only "neutral ground" pumps may be used on positive ground systems.

- Is the pump self-priming?

- Yes

- Will the pump push and pull fuel?

- The FR pumps will "push" and "pull" fuel, but it is preferable to "push" fuel.

- Are the pumps Coast Guard approved?

- The marine models (FRB-13, FRB-16, FRB-20, FRB-22 and FRB-23) are coast guard approved and include additional corrosion protection for use on diesel or gasoline marine applications which meets the ASTM B-117 spec.

- Should I install a pre-filter to protect the pump?

- Walbro recommends a 70 micron filter.

- On carbureted applications why do you recommend that the pump be mounted 12? below the carburetor?

- This is recommended as a precaution in case of carburetor float failure, so the fuel is not siphoned easily.

- Will fuel flow through pump even when the pump is not running?

- Yes

- What size fuse should be used with FR pumps?

- A 5 amp fuse is recommended.

- What if I already have a mechanical pump in my system?

- The electric fuel pump is easily installed in the fuel line between the fuel tank and carburetor. The old mechanical fuel pump can be removed and the mounting hole covered OR the electric pump can pump right through the mechanical pump as long as the mechanical pump's diaphragm is not ruptured.

- How do I know the pump is working?

- FR pumps will produce an audible clicking sound when cycling. FRA and FRC pumps will run at a constant rate (fixed frequency), regardless of the fuel flow rate. FRB and FRD pumps will slow their cycling as the fuel flow rate drops.

- How do I know if I need to replace the filter on my FRB or FRC?

- The filter may need to be replaced if you are experiencing insufficient fuel flow. To replace filter, use a 19 mm or 3/4" hex wrench to loosen screw on the bottom of fuel bowl.

FR Fuel Pump Series Specification and Design PDF version 1

FR Fuel Pump Series Specification and Design PDF version 2